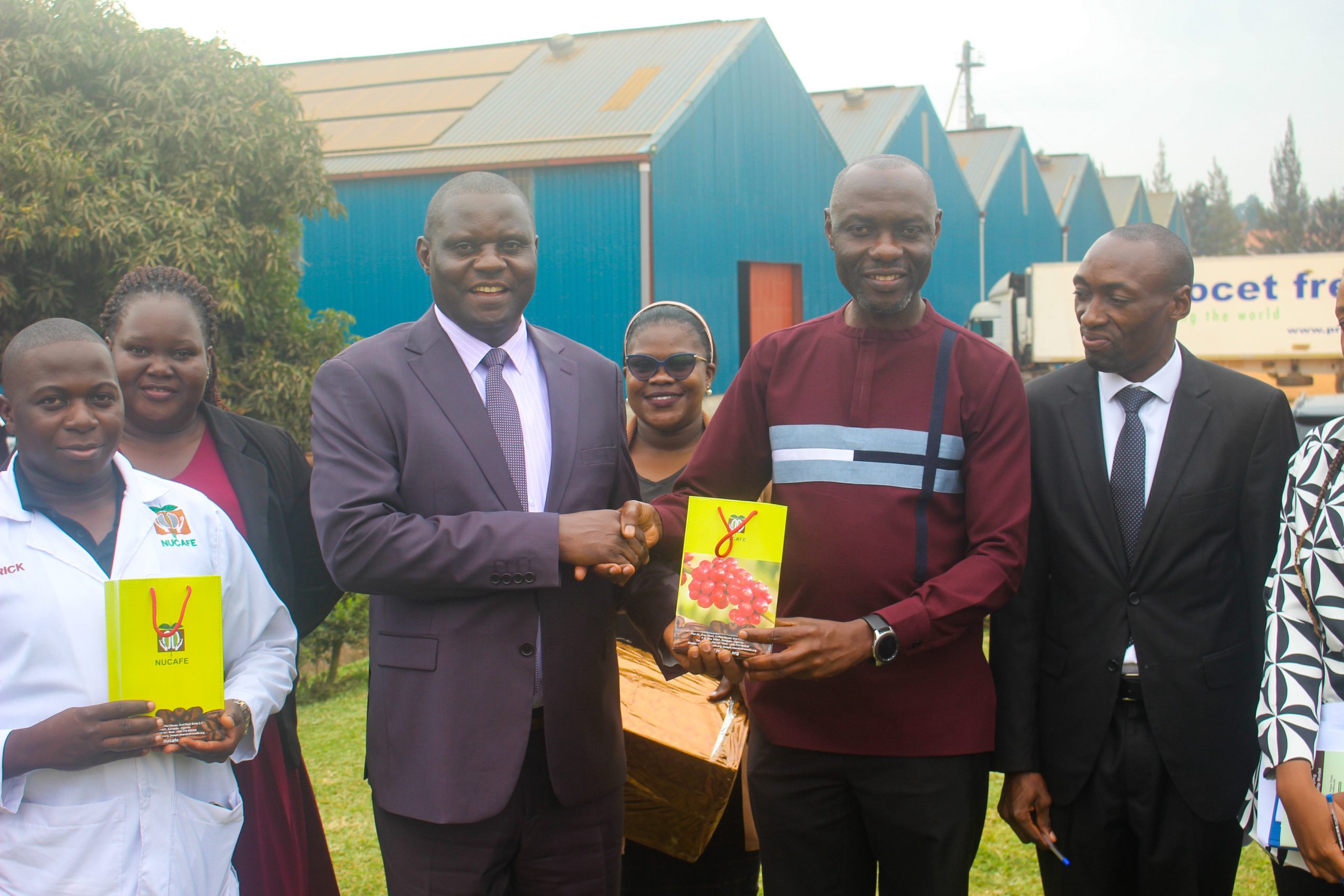

NUCAFE Executive Director, Mr. Joseph Nkandu introduces guests to the newly constructed Industrial Solar Power Plant.

Become a Member Jobs & careers Contact Us

Translate here

Welcome to NUCAFE

NUCAFE is a hybrid farmer-owned social enterprise founded in 2003 having its business entity, NUCAFE Grading Limited.

NUCAFE is the trademark and one of the brands used by NUCAFE Grading Limited in all its operations.

From humble beginnings in pursuit of its vision, “Coffee Farmers profitably own their coffee along the coffee value chain for sustainable livelihoods, consumer satisfaction, and societal transformation”.

Mission

To establish a sustainable market-driven system of coffee farmer enterprises/organizations which are empowered to increase their…

Vision

Coffee farmers profitably own their coffee along the value chain for sustainable livelihoods and customer satisfaction leading to societal…

Core values

Shared Value, Creativity and Innovation, Social Entrepreneurial Culture, Supply chain

© 2007 - 2024 Copyright National Union of Coffee Agribusinesses and Farm Enterprises (NUCAFE). Designed by Lwegatech.